- Mon - Fri: 9:00 AM - 19:00 PM

We deal and distribute the products like S500, S790 and Pinpoint Range.

S500

An easy-to-use scalable turnkey solution for the functional & diagnostic test of your LRUs, PCBs and electronic assemblies. The S500 system self-test provides a check on the correct operation of hardware and software resources..

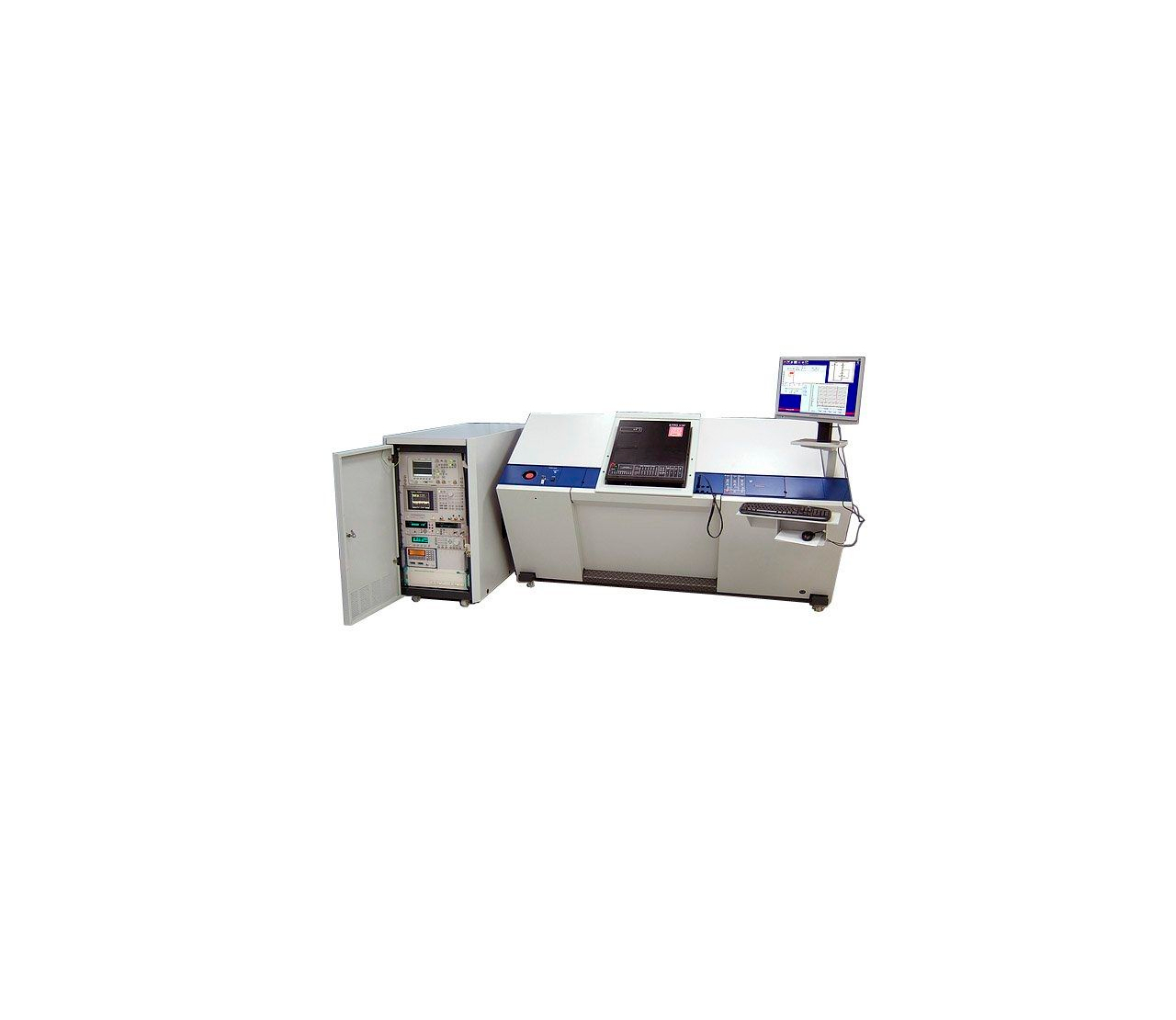

S790

The ultimate precision test ATE system for PCBs and electronic assemblies. The S790 Series2 - combines advanced hardware and software technologies with intelligent diagnostics providing an ATE that addresses every aspect of electronic PCB test in today’s challenging test environments.

PinPoint II R

PinPoint II R provides industry-leading capability for the test and fault finding of the most challenging PCB (or CCAs). Allowing you to select and apply different test techniques on a single circuit, you can ensure maximum fault coverage.

PinPoint Alpha

The PinPoint Alpha system is a flexible, adaptable and modular PCB and IC fault finding system, which allows you to apply different electronic test methods to obtain maximum test coverage and fault detection.

PinPoint Sigma

The PinPoint Sigma is designed as an affordable, flexible and modular PCB test and fault finding system. With the ability to apply multiple different test methods at the PCB edge connector or to each IC and device in-circuit

Our Best Services

We address electronic equipment repair issues in the fields of motion control and positioning systems equipment.

We repair Power Supply Units ranging from Computer Equipment to Medical Devices, Industrial equipment .

We repair for SCADA and HMI equipment for a broad range of customers.

WORKING WITH YOU TO HELP DEVELOP A SELF SUFFICIENT CAPABILITY FOR LONG TERM SUPPORT OF ELECTRONICS

Professional project management and support from the Nikirams team helps ensure your project can be implemented smoothly, rapidly and demonstrate early results. Building on early success the infrastructure for a world class electronics repair and overhaul capability is formed and developed

Developed over 40 years’ dedicated to the test and repair of electronic systems means the technology and know-how invested in the Nikirams products and engineering team is unique in the industry. Working in partnership with you to enable the transfer of this technology and know-how through equipment and tailored training programmes means you can start developing a self-sufficient world-class facility for the repair and overhaul of your electronic systems. The solution comprises of the

TRANSFER OF KNOWLEDGE

TRANSFER OF TECHNOLOGY KNOW-HOW

WORKING TOGETHER

We source all of our spare parts requirements which meets the OEM component specification.

We employ the advances in the area of reverse engineering to offer a fast, flexible and accurate service.

We use advanced analysis techniques to dig deep into any electronic problem and identify the root cause of same.

Enabling a self-sufficient capability for the repair and overhaul of electronic systems, LRUs and PCBs

Implemented and supported in-country the CORE solution provides a solid foundation on which to build a world-class and self-sufficient capability for the overhaul, repair & maintenance of most types of electronic LRUs, PCBs and systems with.

| CREATION OF HIGH-TECHNOLOGY JOBS | On-going success story in line with ambitious economic & political objectives of good government |

|---|---|

| STATE-OF-THE-ART EQUIPMENT AND PROCESSES | An unrivalled capability for the test, fault identification, and repair of electronics. |

| TRANSFER OF TECHNOLOGY KNOWHOW AND KNOWLEDGE JOBS | Tailored training programmes, coaching and on-the-job training |

| EXTENDED WORKING LIFE FOR SYSTEMS | By minimising the re-work required through the accurate identification of failures and in-depth test |

| IMPROVED SYSTEMS AVAILABILITY | Through the reduction of turn-around time for repairs |

| REDUCED THROUGH-LIFE COSTS | Reduction of inventory & extending working life |

| EARLY RESULTS WITH VISIBLE PROGRESS | Fully managed implementation helping ensure early results and equipment utilisation |

Whether you are considering a major project or want to spread the investment over several years with a phased implementation, the CORE solution is flexible to allow progress at your pace and available finance. The solution can be tailored to meet your current requirements and future

growth plans while ensuring meaningful achievements are possible at each step such that you start earning payback on your investment early in the project